Saving energy in the brewery

Saving energy is becoming more and more important, especially in sectors with high energy consumption such as the brewing industry. In view of rising energy prices, breweries are looking for ways to reduce consumption, especially in the area of cooling in the fermenting cellar, which can account for up to 40 % of total energy requirements.

Technological advances and optimizations have already made it possible to significantly reduce the energy requirement per hectolitre of beer. One example of such innovations are the Sigrist turbidity meters, which are used to monitor and control the brewing process. These devices are characterized by low power consumption, which has even been reduced by up to 50 % with the latest generation.

However, the real advantage of Sigrist devices lies not only in their low energy consumption, but also in their ability to shorten the fermentation time. Reducing the fermentation time by 1 to 2 days can reduce energy consumption by up to 10 % and prepare the equipment for the next brew more quickly. This not only leads to energy savings, but also to increased capacity and improved beer quality.

In times of rising energy costs, it is crucial that breweries continue to look for efficient solutions to operate more sustainably while maintaining or even improving the quality of their products.

Contact distribution partner

Für Wasser, Industrielle Prozesse, Verkehr & Umwelt kontaktieren Sie unseren Hauptsitz.

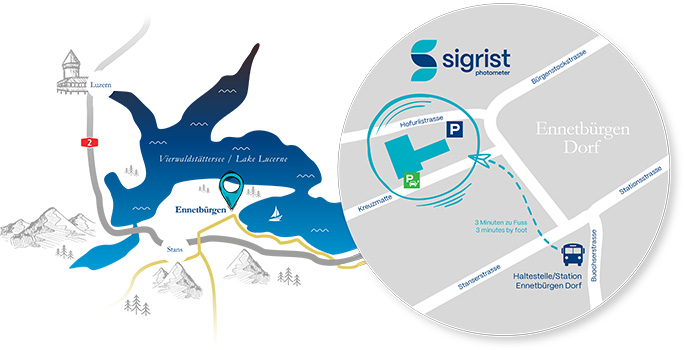

For water, industrial processes, traffic & environment please contact our headquarters

Für Wasser, Industrielle Prozesse, Verkehr & Umwelt kontaktieren Sie unseren Hauptsitz.

For water, industrial processes, traffic & environment please contact our headquarters