Turbidity measurement before disinfection

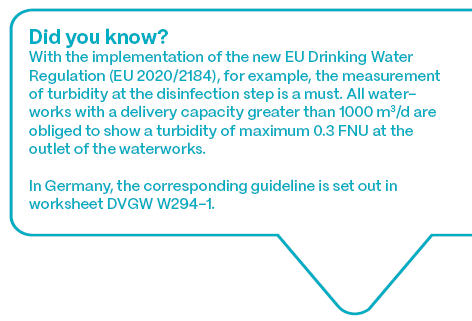

The final step in drinking water treatment is often disinfection. It ensures that no microbiological contaminants such as coliform bacteria (E. coli) are present before the water is fed into the network. At this process step, the turbidity is already rather low. Instruments must therefore measure accurately and reliably detect even the smallest changes in turbidity.

From the raw water intake, all treatment steps are of a physical nature, i.e. the water is processed by means of filtration, decantation or adsorption. However, microbiological contaminants such as E. coli cannot be removed in this way. With high colony counts, these can lead to gastrointestinal diseases and must be removed.

Surface water is always disinfected. It can be carried out by means of ultrafiltration, UV irradiation or chemically. In the latter case, the water is treated with chemicals containing chlorine (HClO, ClO2, rarely Cl2); some waterworks also use ozone.

In some groundwater works, only transport chlorination is carried out to prevent microbiological growth in the pipe network.

The disinfection is cost-intensive and must therefore be controlled efficiently. The turbidity is already low at this process step. The instruments must therefore measure accurately and reliably detect even the smallest changes in turbidity. If the input turbidity is too high, the water is discarded. This ensures the effectiveness of expensive UV systems, for example. However, an ozone system or the addition of chlorine can also be dosed based on the input and output turbidity.

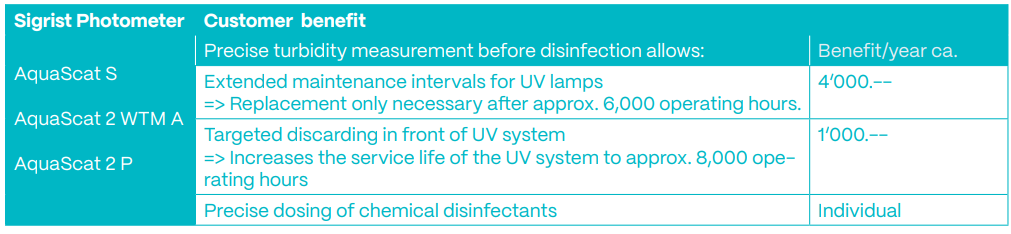

The Customer Benefit

The Solution

The AquaScat S is particularly suitable for monitoring the disinfection step. This probe can be used to measure the water directly in the pipe. This avoids wasting water that has already been treated. The ideal solution is two AquaScat S and one SiCon M (control unit).

The first AquaScat S monitors the input turbidity during the disinfection step. If this is too high, the water can be discarded. In Germany, for example, if the turbidity is > 0.2 FNU, the water is not fed into a UV disinfection system, as this would reduce the disinfection performance and increase the maintenance effort. The turbidity limit value can be defined conveniently and intuitively on the SICON M for the first turbidity channel. A signal output (analog, digital, serial) can also be used and fed directly into the control system.

The second AquaScat S monitors the turbidity after disinfection. The good resolution of the devices enables efficiently detect even the smallest changes in turbidity.

Further Practical Measuring Tasks

The measurement task can also be carried out very well with an AquaScat 2 WTM A or an AquaScat 2 P. Both measure the smallest changes in turbidity and are comparable to the AquaScat S in terms of the required specifications.

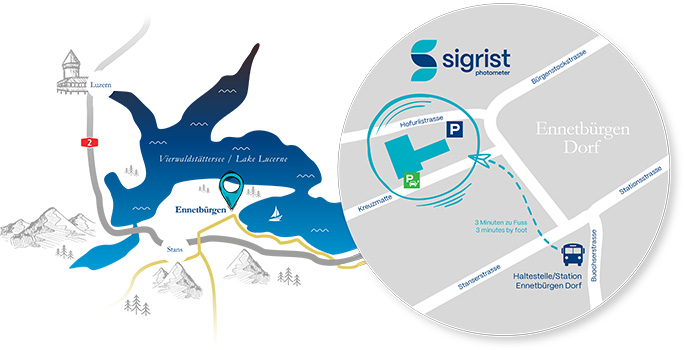

Contact distribution partner

Für Wasser, Industrielle Prozesse, Verkehr & Umwelt kontaktieren Sie unseren Hauptsitz.

For water, industrial processes, traffic & environment please contact our headquarters

Für Wasser, Industrielle Prozesse, Verkehr & Umwelt kontaktieren Sie unseren Hauptsitz.

For water, industrial processes, traffic & environment please contact our headquarters