A. Rogner

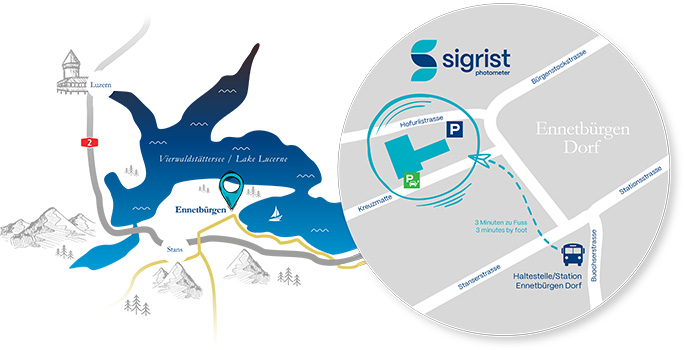

SIGRIST-PHOTOMETER AG, Hofurlistrasse 1, CH-6373 Ennetbürgen, Switzerland

In many production processes of the chemical, petrochemical and

pharmaceutical industry, color is an important parameter for the quality of

the product or the production process. Might be the exact color value, might

be the requirement of an ideally colorless product, might be the color range

in a specific production step of a product. Examples are decoloration

processes as in phthalic anhydride, paraffin or naphta or color measurement

in hydrocyanic acid, oils, and fuels. Moreover, color or absorption

measurement can be used to determine the concentration of specific

substances by their characteristic absorption, e.g. in copper or chromium

solutions for plating processes or ozone concentration in air.

With 60 years of experience in process measurement, SIGRIST now offers

the ColorPlus as the state-of-the-art in-line color monitor. The well-proven

dual-beam technology with measuring and reference beam enables a rather

accurate and stable measurement by eliminating all influence of temperature,

aging, etc. Using up to three different wavelengths out of a range from

254 nm UV through the visible up to 700 nm red light all standard color and

UV absorption can be covered. Turbidity compensation is available as an

option. The range is from lowest colors (<1 Hazen or 30 Saybolt) up to

6000 E/m. For the flow cell we can offer customer specific in-line and

bypass designs out of a variety of materials as stainless steel, PVDF,

Hastelloy, etc. also including special options as heating or cooling

jackets. The ColorPlus comes in a compact and rugged stainless steel

housing, optionally available in an ATEX Eex-p version for use in hazardous

areas.

We want to give here two specific application examples, which have been

realized in various installations:

ASTM color in gasoil

Gasoil is a preproduct in the refining of diesel fuel and light fuel oil,

partly also used directly as a fuel. The color of the gasoil normally might

not exceed 2.5 to 3 ASTM color units. Higher values are a hint for a

malfunction of the process and so this measurement is crucial for the

quality of the gasoil or subsequent refining steps. At a value of 5 ASTM,

the process is running off and has to be interrupted. The measurement is

done at a wavelength of 520 nm. The temperature is around 110°C.

Hazen-color in phthalic anhydride

Phthalic anhydride is widely used in industry in the production of dyes

(rhodamine, anthraquinone derivatives), insecticides, plasticizers, in

pharmacy, in analytic chemistry, etc. The colorness of the material is an

important quality issue and thus has to be measured continuously. The

typical range for the measurement is 0..20 Hazen, a range, where the human

eye can no longer detect any coloration. The measurement is done at a

wavelength of 390 nm. Another important fact to be taken into account is

maintaining the product temperature at least at 160°C to prevent

crystallization of the anhydride. For this reason an in-line flow cell with

steam heating jacket is used.

Other applications have been realized for color measurement in

Hydrocyanic acid (0..600 Hazen), color in Acrylic acid (0..10 Hazen),

concentration of copper sulphate solution for electroplating (0..120 g/l),

chlorine dioxide concentration in desinfection or bleaching solutions

(0..15 g/l), residual ozone concentration in ultrapure water (0..50 ppb) or

ozone concentration after the generators (0..300 g/m3).

Products: ColorPlus in-line |

ColorPlus Ex in-line | ColorPlus bypass |

ColorPlus Ex bypass |

ColorPlus O3 Gas |

ColorPlus O3 Water